Global Market Insights 2025 The Evolution of Manual Glass Cutting Tables

In the rapidly evolving world of glass processing, the Manual Glass Cutting Table has emerged as a vital tool for artisans and manufacturers alike. As the demand for precision and quality in glass cutting continues to grow, so does the need for innovative solutions that enhance efficiency and craftsmanship. This blog will explore the significant advancements in manual glass cutting technology, highlighting how these tables have adapted to meet the challenging needs of contemporary markets.

By 2025, we expect to witness a transformation in the use of Manual Glass Cutting Tables, as they incorporate new materials, designs, and functionalities that cater to a diverse range of applications. From intricate custom designs to large-scale production, the evolution of these tables reflects broader market trends and consumer preferences. Join us as we delve into the current landscape and future potential of manual glass cutting, revealing insights that will be essential for professionals in the industry to harness the full capabilities of this essential equipment.

The Rise of Manual Glass Cutting Tables in Industrial Settings

The industrial sector is witnessing a significant resurgence of manual glass cutting tables, driven by the growing demand for precision and flexibility in glass processing. Unlike automated cutting systems, manual tables empower skilled artisans to handle various glass types and thicknesses with remarkable accuracy. This adaptability makes manual glass cutting an attractive option for small to medium-sized enterprises that require custom solutions without the hefty investment associated with fully automated machinery.

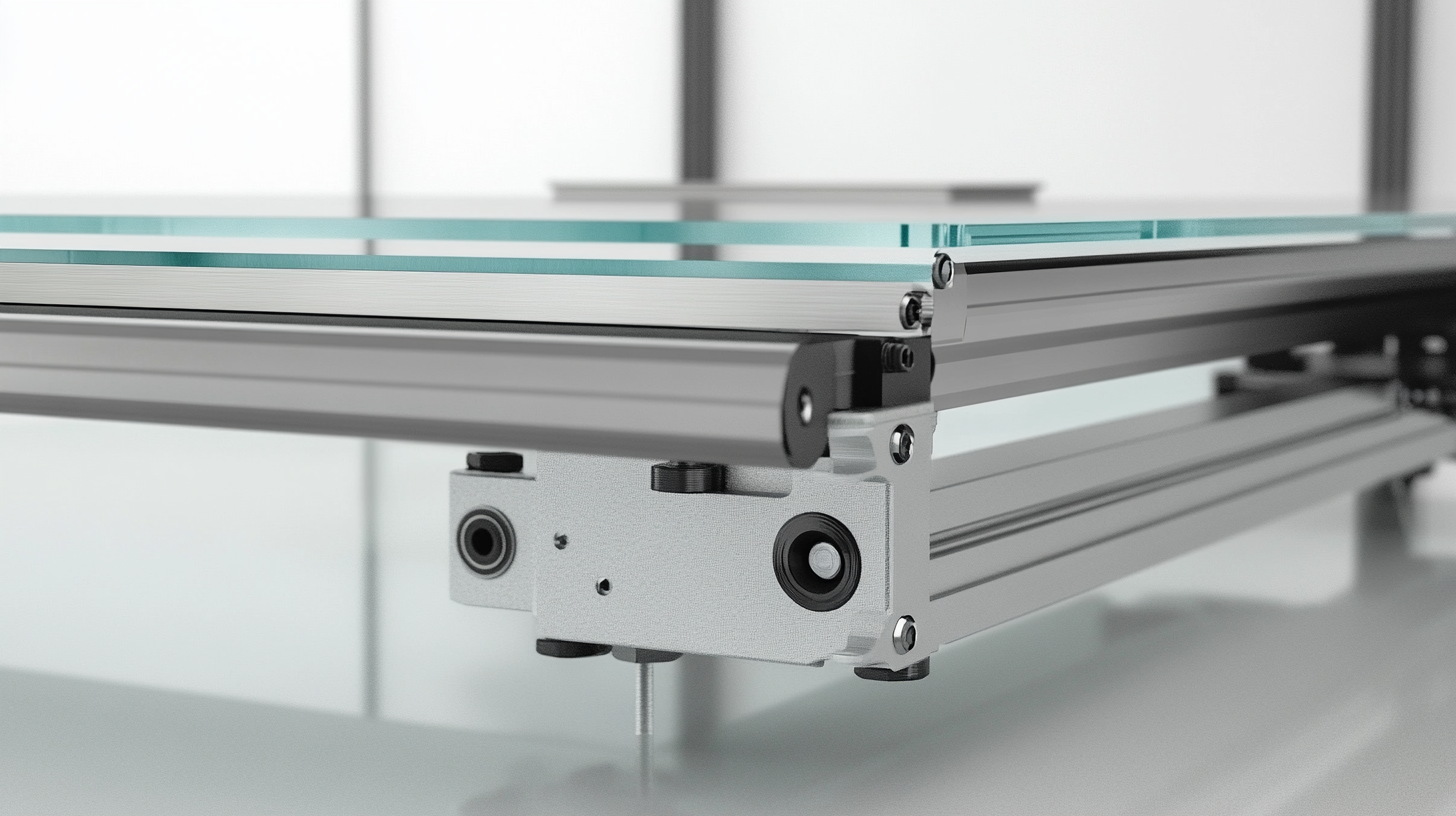

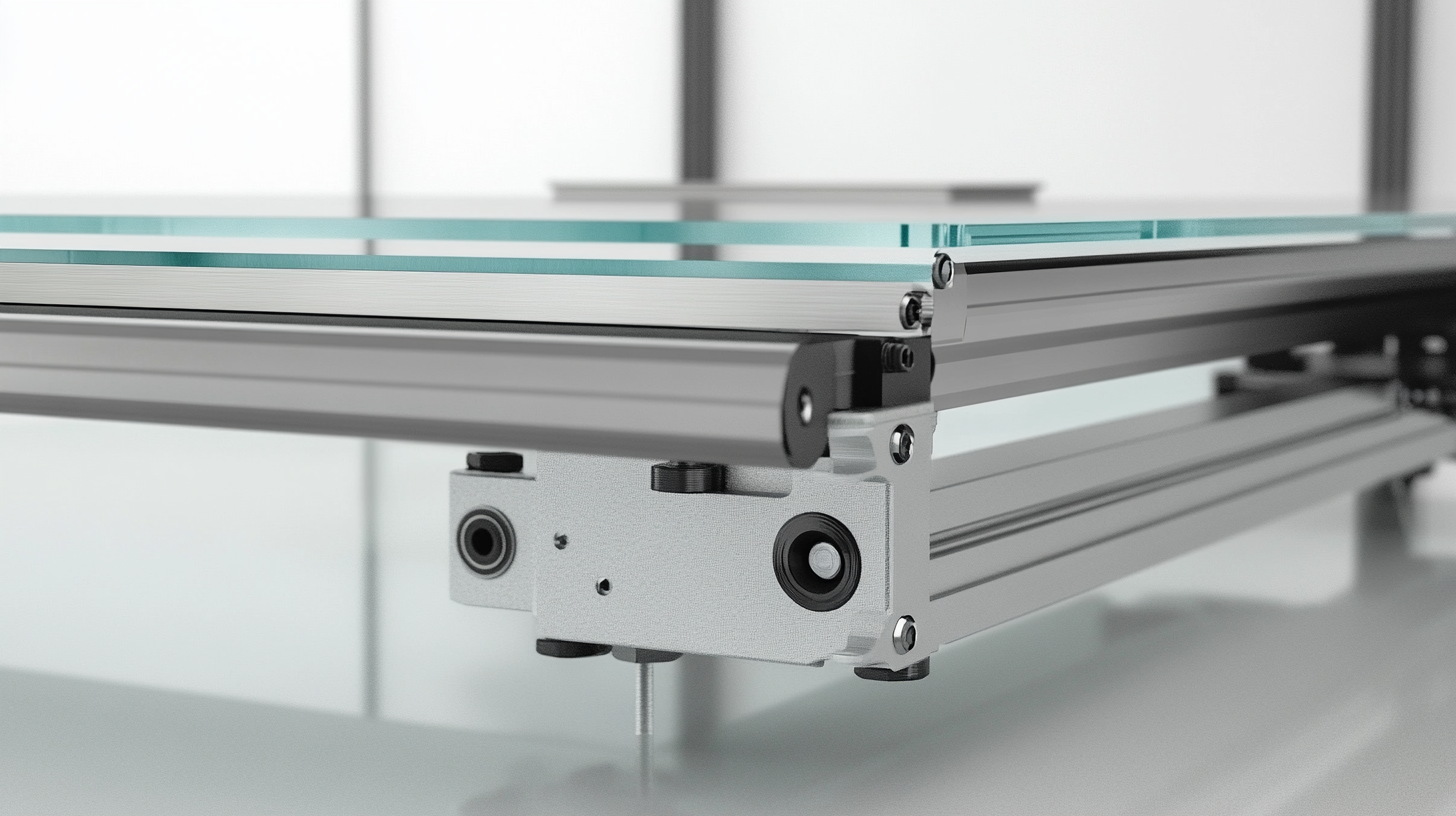

In recent years, the evolution of manual glass cutting tables has been marked by advancements in material and design, enhancing their functionality and ease of use. Modern tables often feature ergonomic designs that minimize operator fatigue, while innovations in cutting tools and blade technology ensure cleaner cuts and reduced waste. As industries increasingly focus on sustainability, the ability to efficiently utilize raw materials and minimize scrap has positioned manual tables as a viable choice for environmentally-conscious firms.

Moreover, the rise of these tables is not only limited to traditional glass processing sectors. The booming fields of interior design and custom architecture have amplified the need for bespoke glass products, further fueling the demand for manual cutting. Craftsmanship in glasswork is being celebrated, and the hands-on element of manual cutting not only yields unique products but also fosters a deeper connection between artisans and their craft, marking a delightful blend of tradition and modernity in today’s industrial landscape.

Evolution of Manual Glass Cutting Tables in Industrial Settings (2025)

This chart illustrates the projected growth of the manual glass cutting tables market from 2020 to 2025, showcasing a significant rise in industrial applications and market demand.

Key Features Driving the Evolution of Glass Cutting Technology

The landscape of glass cutting technology is undergoing significant transformation, driven by innovations in manual glass cutting tables. As the industry shifts towards more efficient and precise methods, several key features are emerging that are redefining the way glass is processed. These advancements not only enhance productivity but also elevate the quality of finished products.

One of the most notable developments is the integration of ergonomic designs into manual glass cutting tables. These designs prioritize user comfort, reducing the risk of repetitive strain injuries among operators. Furthermore, the incorporation of advanced materials and finishes increases durability and maintenance ease, allowing for longer service life and improved performance under heavy usage conditions. This attention to operator well-being and equipment longevity is pivotal in fostering a sustainable work environment.

Additionally, modern manual glass cutting tables are equipped with precision guiding systems that facilitate more accurate cuts. These systems reduce errors and waste, optimizing material usage and ultimately lowering production costs. The advent of adjustable LED lighting also plays a crucial role, providing better visibility of cutting lines and enhancing the overall cutting experience. As these features continue to evolve, the manual glass cutting tables of tomorrow promise to merge technology and craftsmanship in ways that revolutionize the glass industry.

Global Market Insights 2025 - The Evolution of Manual Glass Cutting Tables

| Feature | Description | Impact on Technology | Market Trend (%) |

| Precision Cutting | Advanced tools that allow for higher accuracy in cutting glass. | Enhances product quality and reduces waste. | 15% |

| User-Friendly Interface | Intuitive controls that simplify the cutting process. | Decreases training time and increases operational efficiency. | 20% |

| Portability | Lightweight designs enabling easy transportation. | Expands usage in various locations and applications. | 10% |

| Smart Technology Integration | Incorporation of sensors and IoT for real-time monitoring. | Improves efficiency and predictive maintenance. | 25% |

| Eco-Friendly Materials | Use of sustainable resources in glass cutting tools. | Reduces environmental impact. | 18% |

Comparative Analysis: Manual vs. Automated Glass Cutting Solutions

The evolution of glass cutting technology has seen a marked contrast between manual and automated solutions, each with its distinct advantages and operational dynamics. Manual glass cutting tables have traditionally relied on skilled craftsmanship, giving operators direct control over the intricate process of shaping glass. These tables allow for personalized adjustments, making them ideal for bespoke projects where precision and attention to detail are paramount. Skilled artisans can utilize their expertise to create customized cuts that meet specific demands, which has long been the hallmark of manual techniques.

However, the rise of automated glass cutting solutions presents a formidable alternative that harnesses technology to enhance productivity and efficiency. Automation reduces the margin for human error, delivering consistent quality in outputs. With advancements in robotics and precision cutting technology, automated systems can process larger volumes of glass more quickly than their manual counterparts. These systems are increasingly integrated with sophisticated software that can optimize cutting paths and minimize waste, contributing to a more sustainable production process.

The consideration of energy management also plays a vital role in this transformation. As manufacturers adopt solar technologies, the operational costs associated with energy consumption diminish, making automated solutions not only efficient but also economically viable. This shift aligns with a broader trend in industry towards embracing technology that enhances reliability and reduces costs, mirroring advancements in waste separation systems that leverage sensor technology and deep learning to tackle challenges in recycling. As the industry evolves, the balance between manual craftsmanship and automated precision will define the future landscape of glass cutting solutions.

Future Trends Impacting Manual Glass Cutting Table Design

The manual glass cutting table market is witnessing a remarkable transformation, propelled by technological advancements and changing industry demands. As we look toward 2025, several future trends are set to influence the design and functionality of these essential tools in glass processing.

One of the most significant trends is the integration of ergonomic principles into the design of manual glass cutting tables. As manufacturers become increasingly aware of workplace health and safety, tables that accommodate various user heights and postures are gaining popularity. This shift not only enhances user comfort but also boosts productivity, allowing glassworkers to perform their tasks with greater precision and less strain.

Another major influence on design is the growing emphasis on sustainability. Materials used in manual glass cutting tables are evolving, with a focus on environmentally friendly alternatives that reduce the carbon footprint. Innovations such as recycled composites and sustainable wood are being considered to not only improve the table's durability but also to appeal to eco-conscious businesses. Additionally, the inclusion of features that minimize waste during the cutting process is becoming a priority, aligning with industry-wide initiatives towards sustainability.

Lastly, the rise of automation and smart technology is starting to penetrate the realm of manual glass cutting. While the essence of manual cutting lies in skilled human oversight, integrating smart sensors and digital guides can enhance accuracy and reduce errors. This technology not only aids in real-time tracking of cutting processes but also allows for data collection to streamline operations. As these trends continue to evolve, the manual glass cutting table of the future will become a more sophisticated, efficient, and user-friendly tool.

User Experience and Training: Enhancing Efficiency with Manual Tools

In the fast-evolving world of glass cutting, understanding the user experience is paramount. Manual glass cutting tables have undergone significant transformations, focusing not just on efficiency but also on enhancing the overall experience for artisans and technicians. The tactile nature of manual cutting requires a blend of skill and intuitive design, where each cut can significantly impact the final product’s quality. By placing an emphasis on user-friendly features, manufacturers are improving ergonomics and accessibility, making it easier for professionals to achieve precision without compromising comfort.

Training plays a critical role in maximizing the potential of manual tools. As technology advances, the foundational skills of glass cutting must be preserved and enhanced. Effective training programs should not only focus on the mechanics of using cutting tools but also integrate techniques that enhance creativity and problem-solving. Workshops and tutorials that engage users in hands-on practice with the latest manual equipment can bridge the gap between traditional skills and modern expectations, fostering a new generation of glass artisans who are both skilled and innovative.

Moreover, a responsive design that incorporates feedback from users can significantly refine the tools themselves. Listening to those who work daily with manual glass cutting tables allows for continuous improvements in functionality and safety features. With a focus on user experience and a commitment to comprehensive training, the glass cutting industry can ensure that these traditional tools remain relevant while promoting artisans' efficiency and creativity for years to come.

Home

About Us

Products

UPVC PVC Window Machine

Aluminum Window Machine

Glass Cutting Machine

Glass Edging Machine

Insulating Glass Machine

Glass lifting machine

Glass Washing Machine

Glass Laminating Machine

Glass Sandblasting Machine

Glass Drilling Machine

CNC Glass Working Center

CNC Non-Metal Cutting Machine

The Other Glass Machinery

Application

Download

News

Contact Us